New Profile Design Reduces EMI and Assembly Costs - an applications noteby Christian Brull, EMC Product Manager-Europe, Schlegel Systems, Inc. |

Consider the case of a leading telecommunications company faced with the challenge of shielding inner compartments within a larger enclosure. The problem: a small aperture between the enclosure's cover and the top side of the metal walls allowed EMI to radiate from one compartment to another. The manufacturer tried to correct the problem by bending the inside walls into a small L-shape and using a small conductive elastomer gasket taped onto the flat surface touching the enclosure's cover. However, this method proved too costly when incorporated into the manufacturing process.

The enclosure had top-cover access only. Several compartments were separated by vertical metal walls, which were the source of the EMI leakage. Controlling EMI at the junction of the walls and the top cover proved to be a difficult task. Not only did the gasket have to shield the aperture between the wall and the cover, it also had to be simple to install and able to withstand compression cycling when the top was removed periodically.

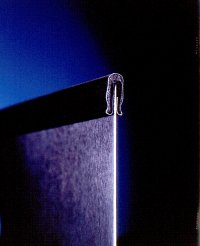

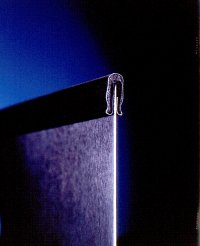

Working with the enclosure designers, Schlegel Systems helped develop a totally new attachment method for an EMI shielding gasket. Called the Mini-Clip gasket, or E93, it uses Schlegel's proven shielding technology, but features an attachment method that needs neither tape nor fasteners. The core of the Mini-Clip gasket is compression-resistant, open-celled polyether polyurethane foam. Mini-Clip gaskets are clad Schlegel Systems' signature fabric, made of silver-plated woven nylon ripstop with durable C2 corrosion-resistant coating.

The Schlegel attachment method makes all the difference. Rather than tape or fasteners, the mini-clip has a plastic clip that snaps down over the flange and is completely wrapped with conductive fabric. It increases the contact surface and therefore improves the shielding efficiency. Because the attachment clip is manufactured as an integral part of the profile, this gasket provides greater stability and better retention forces in high-shear and sliding applications where pressure-sensitive adhesive needs to be avoided or eliminated. Mini-clips are designed to fit sheet-metal flanges in the range of .019 inches to .059 inches (0.5mm to 1.5mm), with plans to make additional profiles to fit larger size flanges.

|

| A new min-clip E93 EMI shielding gasket from Schlegel Systems Inc., a member of the UniPoly group of companies, is a low-cost solution for controlling EMI in electronic devices. The core of Schlegel's mini-clip gasket is a unique open-celled plyether polyurethane foam in a high-resiliancy formula. SCHLEGEL mini-clips also employ Schlegel's signature C2 fabric cladding made of silver-plated woven nylon ripstop. |

|---|

Beryllium Copper (BeCU) fingerstock, which is also easy to snap on, was considered. However, slots in between fingers induced loss of material on cut-to-length and therefore increased its cost. As a result, the Mini-Clip EMI shielding gaskets, available in continuous length of two meters and easy to cut without any specific tool, were preferred as an alternative to BeCu fingerstock, conductive elastomers and wire mesh.

Not only is silver easy to recycle, which is in line with the future European Directive on "waste from electrical and electronic equipment", it also is a superior conductor to other metals, especially at higher frequencies. Schlegel Systems' Mini-Clip with flexible, highly conductive fabric makes it an ideal solution to control EMI in a wide range of electronic devices.

For the telecommunications company, the new Mini-Clip-E93 dramatically reduced mounting time and decreased costs by 42 percent over the previous method. In addition to being well-suited for the telecommunications industry, Schlegel Systems' Mini-Clip EMI shielding gaskets are ideal for set top boxes and other applications that demand electrical contact between fixture walls and the cover of an enclosure. Using existing technology in new configurations can make the inclusion of shielding in manufacturing processes easier to control. Schlegel Systems, Inc. is a member of the UniPoly (www.unipoly.com) group of companies, one of the world's leading manufacturers of fluid handling, belting and polymer products. SCHLEGEL EMI shielding products are available in hundreds of standard profiles and custom designs, with attachment options that include self-mounting, clip, rivet and adhesive techniques.

© Nutwood UK Ltd 2001 |

Eddystone Court - De Lank Lane St Breward - BODMIN - PL30 4NQ Tel: +44 (0)1208 851530 - Fax: +44 (0)1208 850871 nutwooduk@nutwood.eu.com |

|

|

|